OUR STORY

Since 2012, the start of its operation. The Martabe Gold Mine had a well–deserved reputation as an industry leader in terms of safety, sustainability, and production processes. With our people at the heart of our business, we use innovative practices and the latest technologies to discover new resources and to mine, process, move and market our products to our future–enabling the delivery products to our customers safely and sustainably. We work collaboratively with our stakeholders to enhance our contribution to sustainable development in North Sumatra and across Indonesia. And more importantly, we want our people and our communities to grow as we grow. We believe that only together we can build a sustainable future now, and tomorrow.

The total concession area containing the Martabe Gold Mine falls under a sixth-generation 30- year Contract of Work between PT Agincourt Resources (the company) and the Government of Indonesia. The initial area set in 1997 was 6,560 km2 but with some renunciations now sits at 1,303 km2 (130,252 hectares). However, following several renunciations, is now 130,252 hectares (1,303 km2) in size. South Tapanuli, Central Tapanuli, North Tapanuli and Mandailing Natal Regencies encompass the Company’s operational areas. The operational area of the Martabe Gold Mine is located in South Tapanuli Regency and currently covers an area of 509 hectares.

TIMELINE OF OWNERSHIP

1997

Founded by Normandy

( JV and Anglo )

2003

Majority owned by

Newmont East Asia

2009

Acquired by G-Resources, Ltd

2016

Acquired by a consortium led by EMR Capital

2018

Acquired by PT Danusa Tambang Nusantara, a subsidiary of

PT Pamapersada Nusantara and

PT United Tractors Tbk, member of Astra

OUR OPERATION

The Martabe Gold Mine is located on the Sumatran fault line, which allowed for formation of mineral flow deposits, making it rich in minerals, including gold and silver. Currently, we operate three open-cut pits, namely Pit Ramba Joring, Pit Barani, and Pit Purnama; and we run a conventional carbon-in-leach (CIL) gold ore processing plant. Haulage Roads, a Tailings Storage Facility, raw water storage tanks, sediment control dams, water polishing plant, a switchyard, fuel depot, workshops and warehouses complete our vibrant and productive enterprise. An analytic laboratory, housing camp, administration building, sports field and clinic round out a community and lifestyle for the miners here in North Sumatra.

EXPLORATION

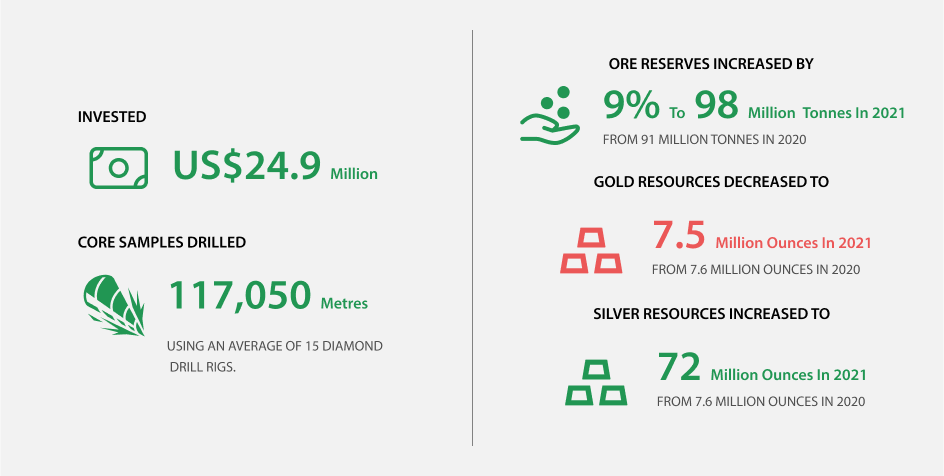

In 2021, we continued our investments in the Exploration Program, with the primary objective of identifying additional resources and reserves.

MINING

The pits of the Martabe Gold Mine provide the ore from which the gold is extracted. Surveying, geo-technical analysis, and planning are essential beforehand in order to open a pit, while during the mining, in addition to these, a variety of means are used to get the rock from the ground, transport this ore, manage the waste rock, and to do all of this safely.

Similar to most gold mining operations, Martabe Gold Mine disposes of tailings in a Tailings Storage Facility, an engineered embankment in a valley. A containment fitted upstream of the embankment stores the tailings while the embankment itself is made of a conventional rock-fill (the overburden) downstream construction and has several distinct internal zones, each serving a specific function.

Purnama Pit, the first to open, began in 2011, followed by Barani in 2016, and Ramba Joring Pits in 2017.

PROCESSING

Our process plant is a conventional Carbon-In-Leach (CIL) plant with a capacity of more than 7 million tonnes of ore per year. The process plant is continuously operated except for scheduled maintenance shutdowns. The extraction of gold and silver from the ore is relatively straight forward.

The essential steps are as follows:

Crushing of THE Ore

Grinding the ore and conversion of this into a wet slurry

Using cyanide to leach the gold and silver from the slurry

ELIMINATING GOLD AND CARBON GRANULES VIA AN ANELUTION PROCESS

adsorption of gold and silver in solution unto carbon granules

recovering gold and silver through electrowinning

smelting gold and silver to produce DORÉ bullion bars. The Martabe Gold Mine refines all of its bullion in certain location/city by third parties.